| Grade | Chemistry | Hardness | Microstructure | Substructure |

| Ultrabra 35 | 4.0-5.0% C | 55-62 HRC | 30-40% Primary Carbides even distributed in austenite | Q235 |

| 26.0-35.0% Cr | ||||

| 1.0-2.0% Mn | ||||

| 0.5-1.0% Si | ||||

| 0.5 % Others | ||||

| Bal: Fe | ||||

| Ultrabra 65 | Cr-Mo-Nb-V-W-B | 55-64 HRC | Complex carbides | Q235 |

| Grade | Properites | Vloume Fraction | Application |

| Ultrabra 35 | High abraasion low to moderate impact |

Primary carbides 30-40% | Truck, dragline, excavator dozer & bucket liners, wear plates, Hopper Linears, screens, chute liners, deflector plates, screw conveyor flights, screed plates,fan housing liners,etc |

| Ultrabra 65 | High abrasion, high impact High temperature |

Commary carbides 30-40% | High temperature abrasion resistance up to 750℃; Paul wurth chutes, sinter bins, high temperature screen plates |

| Overlay | mm | 3* | 4* | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 17* | 20* |

| Inch | 1/8 | 3/16 | 3/16 | 1/4 | 1/4 | 5/16 | 5/16 | 3/8 | 3/8 | 1/2 | 2/3 | 5/6 | |

| Backing Plate | mm | 3* | 4* | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 12* | 12* |

| Inch | 1/8 | 3/16 | 1/4 | 1/4 | 5/16 | 5/16 | 3/8 | 3/8 | 1/2 | 1/2 | 1/2 | 1/2 |

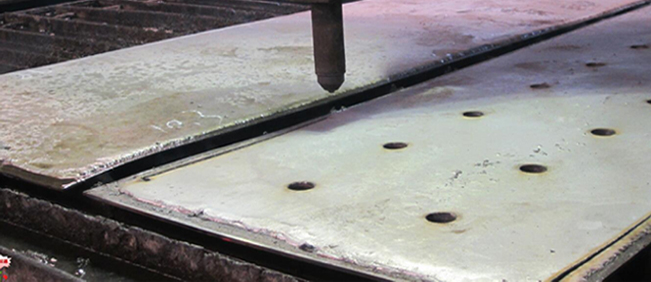

| Manufacturing Process | Advantages | |

| Surface treatment before hardfacing | Shot blasting | Clean base Metal Surface to enhance fusion process |

| Base plate pre-heat | Pre-heat to set temperature | Pre-heat to reduce residual stress |

| Temperature held after weld | Holding temperature for slow cooling process | Post heat to reduce residual stress at fusion line |

| Cooling during welding | Slow Cool | Enhances mechanical strength of the base plate |

| Finished plate flatness | Even | ±3mm per 1.5 linear metres |

| Surface finish | Smooth | Designing for directional flow of material not necessary |

| Friction co-efficient | Low | Excellent for reducing or eliminating hang up or carry back |

| Visible surface weld bead | No visible beads | Smooth surface without weld beads |

| Single pass overlay depth | 3 to 12mm | Uniform microstructure and hardness |

| Fusion dilution depth | 0.5 - 1.0 mm | Low overlay dilution with backing plate. Wear rates become consistent and predictable |

| Microstructure & Hardness consistency | Uniform down to fusion line | Consistent and predicable wear rates |

| Operating temperature | <600 ℃ | Excellent high temperature wear rates |