Ultrafuse U35 & U65 is a revolutionary cco plate in high abrasion resistance and anti stick developed for mobile and fixed plant in application of mining, cement, steel and etc. A unique

manufacturing process is used to make a smooth chromium carbide overlay surface on mild steel base plate. The overlay offers exceeded wear life and is designed for applications in which

the wear caused by severe wear abrasion, low - high impact, with or without high temperatures. Meanwhile, pre-polished Ultrafuse (no weld bends in lower cost for grinding) has unique anti

hang-up properties which make it the satisfactory way for applications in which material sticky material is a problem compared with traditional overlay plate. These superior properties make

Ultrafuse essential in all industries in which wear and/or hang-up is a problem. Ultrafuse can be cut, formed or rolled into shape according to drawings, and then easily attached. The purpose

of this guideline is to detail the basic procedures for working with Ultrafuse U35 & U65, so your company can make maximum use of it.

Dimension Ultrafuse

Major grade U35 & U65 Castel New Material make in normal dimension size 1200×3000, coated areas after cutted. Other size is available in required also. Furthermore, it’s ok for deliverying

with original mild plate no cutted for check. This is only suggested in customer have fabricate capacity.

Cutting Ultrafuse

The overlay of Ultrafuse U35 & U65 contains a high volume of chromium and other elements, 55-62HRC, doesn’t like stainless steel when cutting. Thus, normal methods, such as shearing or

oxyfuel flame cutting, will not be effective. Instead, Ultrafuse U35 & U65 should be cut by plasma arc, water jet, or laser

Forming Ultrafuse

Ultrafuse U35 & U65 made in 1 layer from 4mm-25mm. It can be formed into pipes, cones etc by rolling and/or

pressing. Because of the high hardness of Ultrafuse’s layer in 56-62HRC, there are some restrictions on what

radius the plate can be pressed which are determined by the alloy thickness. Table 4.0 below shows the

minimum recommended radius when pressing with the hardface to the inside for the most common.

| Table 4.0: Ultrafuse Minimum Bend Radius (Overlay inside) |

| Ultrafuse Thickness |

Min Radius(mm) |

| 6+4 |

150 |

| 6+6 |

200 |

| 8+8 |

300 |

| 10+10 |

350 |

| 12+12 |

600 |

Attaching Ultrafuse

Attaching Ultrafuse

Ultrafuse mild steel backing plate allows it to be easily attached to other mild steel surfaces. The most common methods of attachment include perimeter and plug welds, studs and

countersunk bolts. This section will outline the correct procedures that should be used for attaching Ultrafuse to ensure you receive maximum performance.

Joining Ultrafuse

Joining Ultrafuse

Ultrafuse can be joined to itself or other structural steels to form larger panels and/or in the fabrication of bins and chutes. Because of the differing properties of the mild steel and alloy

sides of Ultrafuse fabrication techniques differ slightly from standard structural steels. The main point to consider is that welds on the mild steel side only are considered structural, and

parts are not to be joined to the hardface. Any welding on the hardface is a matter of wear protection only. The following section details the most common methods used in joining Ultrafuse,

however, Castel New Material can tailor designs to suit your requirements.

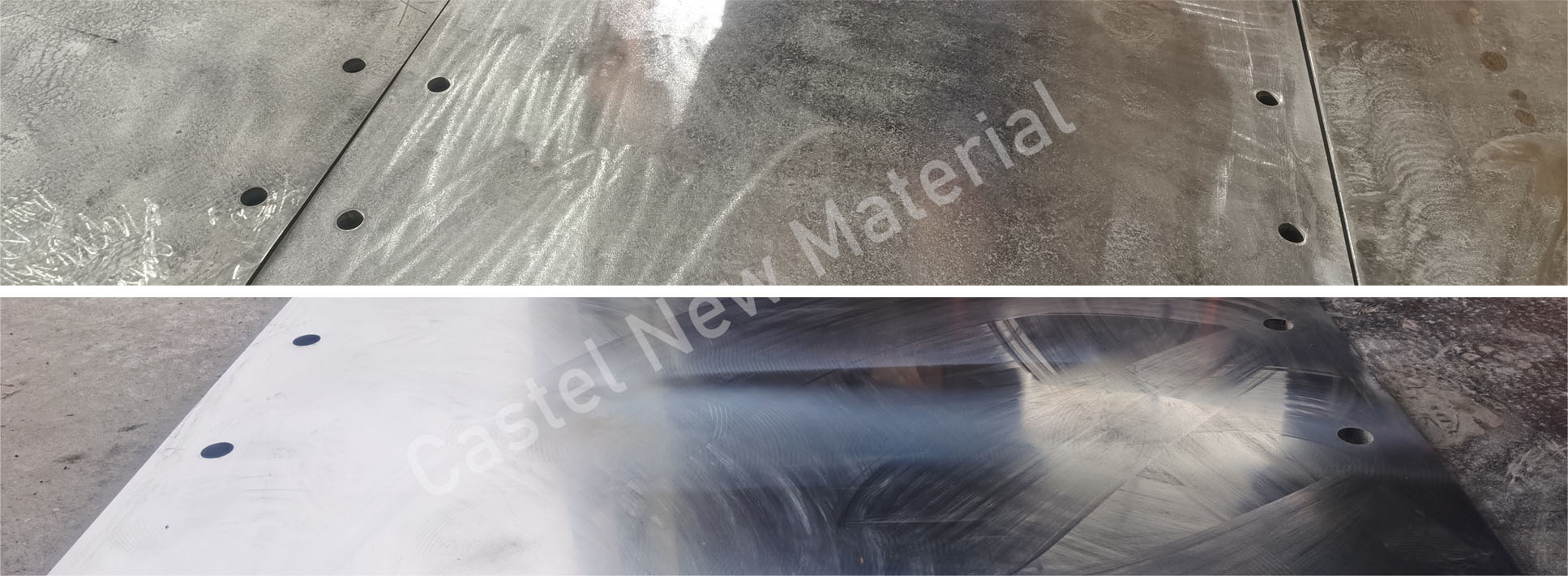

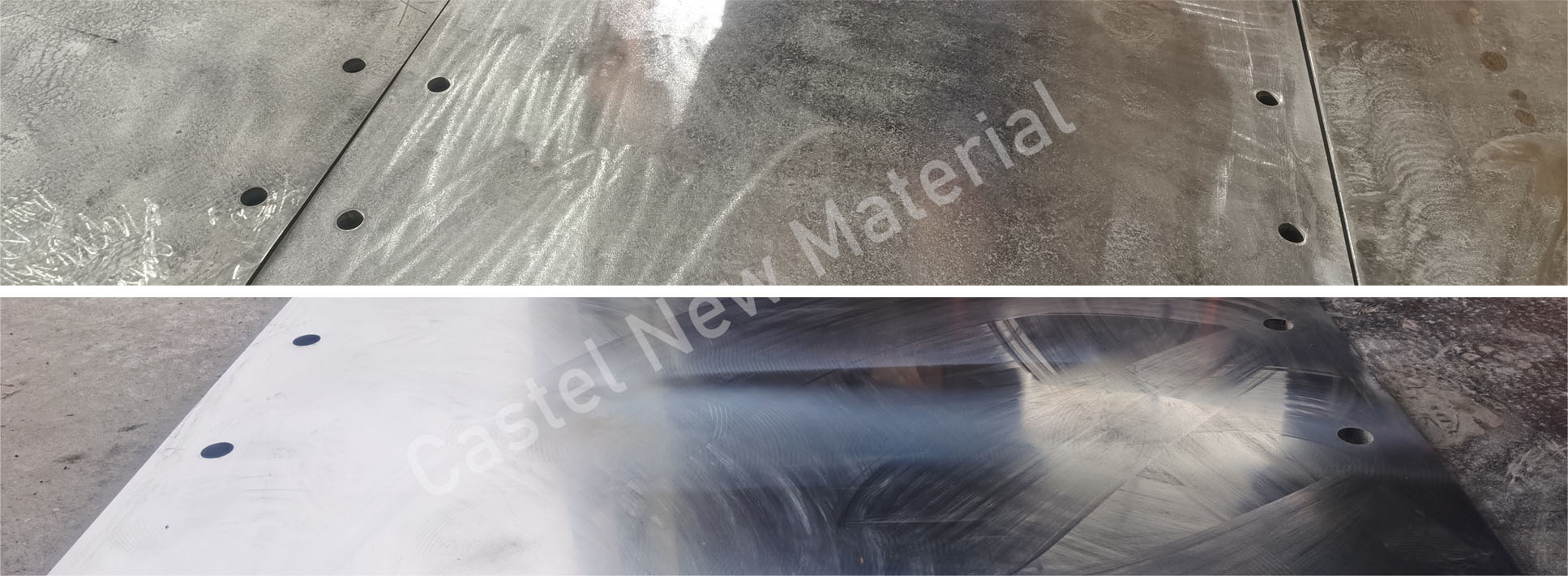

Polishing Ultrafuse

Polishing Ultrafuse

When polished, Ultrafuse is second to none at reducing hang-up and material carry-back. Ultrafuse will polish to a near mirror finish as it wears, but it is necessary to pre-polish Ultrafuse in

most sticky material applications, to accelerate the ‘in-service’ polish. The level of polish required depends largely on material properties and flow conditions. Bulldozer blades, dipper

buckets and truck tray tail liners, for example, only require a light polish as they have a continual flow of material over the surface, which assists the ‘inservice’ polish. Excavator buckets

and the Front Section of Ultrafuse truck kits, however, are continually carrying a ‘dead’ load and require a higher level of initial polish to improve material flow. Castel New Material can supply

Ultrafuse in a pre-polished finish to suit your material conditions and product needs.